Alexa, Sheila, Cryus, Dave, Arnaud

We went to end X to start working on the table there this afternoon. calibrated the PDs on the table, preparing to set up the PLL. Along the way Cyrus helped us with a problem connecting the End X beckoff computer to SVN (restarting the windows machine) and Dave restarted an epics gateway. We saw that we have half the fiber transmission in the wrong polarization, so we will need to adjust it in the morning. We tried to align the two beams to interfer on the beam splitter, but with only 10uW or so in the fiber beam.

We sent the green beam into the transmon, locked the QPD servos, and set up irises once the ETM and transmon offsets were restored. We then raised the front apperature of the EOM, where the beam seemed to be clipping. This greatly improved the beam shape going into the chamber. After that we looked for the return beam, and could not find it. Arnaud had a look at what might have changed for us. He saw a change of about 40urad in HEPI, but that doesn't seem like enough to explain us completely not seeing the beam.

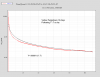

ISC EX PD Calibrations

Fiber rejected polarization 20uW, 0.23V,30dB gain TI=2000 Ohms, meaning responsivity= 0.19A/W

Fiber transmission monitor- 40uW out of fiber, light on PD too small to measure (we are using the old measurement of the splitting ratio 6%) 0.03V, 2000 Ohms, 30dB gain, gives responsivity 0.208 A/W

Laser IR monitor 0.35mW on PD, 1.68V, 2000 Ohms, 30dB, 0.08 A/W. The beam splitter right before the PD has a spliting ratio of 0.55%.

Green laser monitor (this is the beam rejected from the Faraday, so the power observed here depends on any polarization drift as well). with 53 mW of532 coming out of the laser, we have 0.8 mW on this PD, so a splitting ratio of 1.9%

Fiber BBPD (Fiber A) 0.56mW, 2000 Ohms, no gain, 0.14V responsitivty of 0.125 A/W