PRMI is finally aligned and it is now flashing. This should help us to find the POP beam because of higher intra-cavity power and reasonable alignment.

After PRMI was coarsely aligned, I went to ISCT1 and quickly looked for the POP beam, but no beam was found. I also toggeled the HAM1 POP beam diverter, but it didn't help.

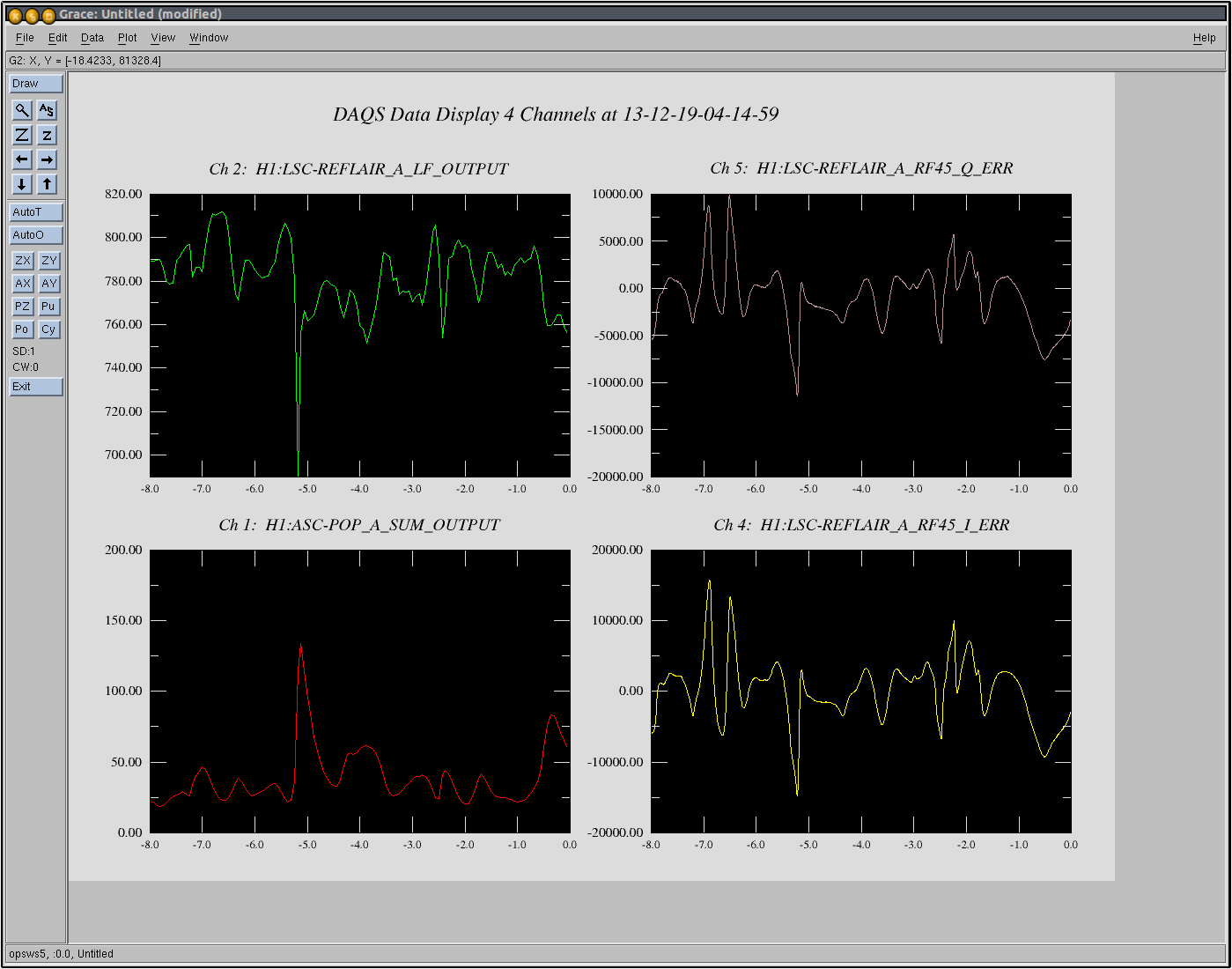

The above plot is an exmaple of time series where you can see that ASC_POP_A goes up to more than 100 counts because of the recycling.

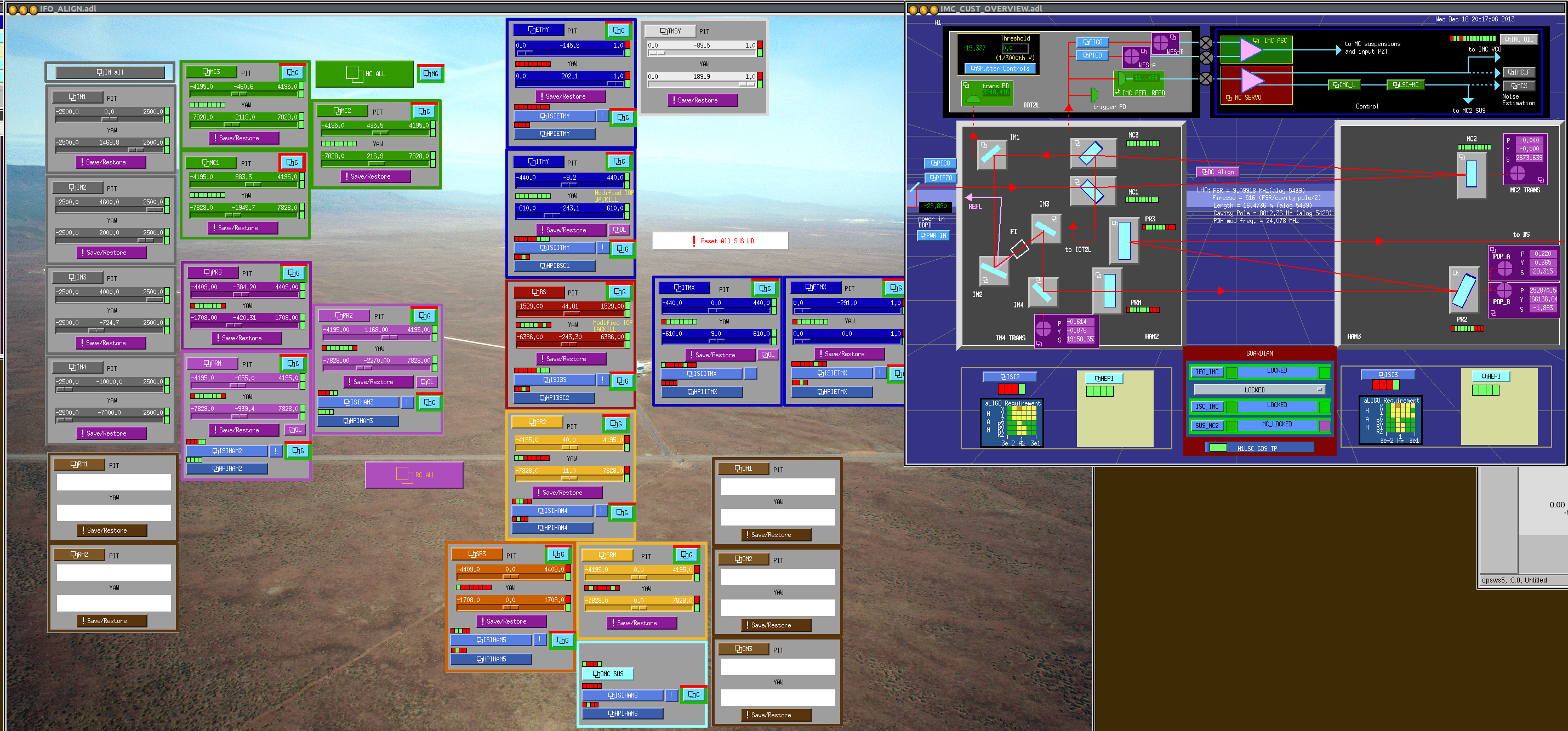

Alignment:

- I started from yesterday's condition in which the beam was centered on ITMX (see alog 8996)

-

Using PR2 and PR3, I adjusted the yaw alignment such that the beam goes through the center of both BS baffle and ITMX.

- This pushed PR2 from -220 to -2270 counts in its DC bias.

- I steered ITMX and found the PRX fringe.

- Then I moved onto the PRY alignment.

-

Keita suggested to take a look at the BS BOSEMs to see if they are at a similar position to that of HIFO.

- According to the BS BOSEMs, the pitch angle is different by -800 urad from that of July 25th.

- This large pitching sort of made sense -- because the BS was tiltled so much that the incident beam needed to be low on BS to hit ITMY. Indeed we saw that the beam was low on BS when PRY flashed.

-

We cahnged the BS DC bias to get the same pitching as July 25th.

- Pitch DC bias went from -159 to 44.81 counts.

- Then, I tweaked ITMY in pitch and yaw and BS only in yaw until PRY flashed.

- We should also check the BS yaw by looking at the BOSEM readouts and possibly steer it back to July 25th while keeping the fringe by steering ITMY yaw.

Sadly, we're finding that aLIGO OLs are not as reliable as OSEMs as a long term reference, just like in iLIGO. According to Kiwamu, all previous PR-X alignment efforts were with the BS angle restored using OLs, not M0 BOSEMs.

Richard says that OLs were fine in iLIGO as far as nobody touched anything.