R. Short, J. Oberling

In an effort to understand our ever-increasing PMC reflected power (and associated loss of PMC transmitted power), today we measured the slopes (output power vs injection current) of the pump laser diodes for the 4S-HP amplifiers. We have power monitors on the pump diodes (calibrated in %, with 100% being our pump diode power at install), but we don't exactly trust them; the monitors for Amp1 show the Amp1 pump diodes are outputting less power than upon install (as we expect after 3 years of almost 24/7 operation), but the monitors for the Amp2 pump diodes indicate we are outputting more power than upon install.

We measure the diode slopes using our water-cooled, 300W-capable roving power meter. Since the pump diodes are ganged together in groups of 2 to their power supplies (1 power supply powers 2 pump diodes, so 8 total pump diodes are powered by 4 power supplies) we have to make sure the diode from the group of 2 that we are not measuring is being dumped; we use an 80W-capable air-cooled beam dump for this. The steps for measuring the slopes are:

- Unplug the fiber for the 1st diode in the group of 2 and install it into a fiber holder that is directed into the power meter

- Unplug the fiber for the 2nd diode in the group of 2 and install it into a fiber holder directed at the beam dump

- Step up the injection current for the relevant power supply in 1A steps (make sure the other 3 supplies are set to 0.0 A), measuring the output power at each step

- Switch the fibers so the one directed at the dump is now directed at the power meter and vice versa

- Step up the injection current in 1A steps, measuring the output power at each step

- Reinstall the fibers into their original ports on the amplifier

- Repeat the above for the remaining groups of fibers

The results are given the 1st attached spreadsheet, with a comparison between today's measurement and the measurement done during install shown in the 2nd attached spreadsheet. Immediately one sees that, despite what the pump diode monitors imply, all 8 pump diodes are outputting more power than they were at install back in 2021. I have no explantion for this right now, we were expecting the output power to be lower (since they've been running almost 24/7 since January 2022, and were up an down mulitple times during install starting with Amp1 first light in October 2021). So we are currently pumping both amplifiers with more pump light than we were at the end of install in January 2022.

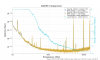

To give you an idea of the degree of overpumping, at install for Amp1 we were running all 4 pump diodes at 9A of injection current; this in turn gave us between 46 W and 47 W of output power from the pump diodes for Amp1. We are now running at 9 A for pump diodes 1 and 2 and 8.8 A for pump diodes 3 and 4, which is giving us between 48 W and 50 W of output power for the Amp1 pump diodes (with the exception of diode 4, which is around 46.5 W). This can and does change the size and location of the output beam waist from the amplifiers, as the thermal lenses in the amplifier crystals change with changes in pump power, which then impacts the mode matching to the PMC. What this doesn't exactly explain is why we've been seeing a slow increase in PMC reflected power (maybe beter mode matching would make it more stable? Maybe by over-pumping the amps we're oversaturating the gain profile to the point where small changes in injection current cause large changes in output beam size/shape?).

In recovering the amplifiers we optimized the pump diode fiber alignment; this was necessary since we deinstalled the fibers from the amplifiers to measure the slopes. This is done by very slightly loosening the fiber connector, enough that you can turn the fiber in its port on the amplifier. With the amplifier on and a power meter measuring the output power, loosen one fiber connector and slowly rotate the fiber while watching the power meter (which will change by several thenths of a W). When the power peaks, tighten the fiber connector. Repeat for the remaining fibers. In doing so we brought the output power of Amp1 to 71.4 W from 69.6 W, and the output power of Amp2 to 141.5 W from ~140.0 W. Interestingly, and not really surprising when you stop to think about it, optimizing the fiber alignment also resulted in a very slight shift in output beam alignment. We didn't immediately notice this until we recovered the PMC and had to do some alignment tweaks to max the transmitted power (we had ~50W reflected at first, but this dropped very quickly with a few Small step size angle tweaks from one of our picomotor-controlled mirrors, indicating the alignment shift was very small). As a result of this we realigned the beam onto the amplifier power monitor PDs. We also had to recalibrate our Amp2 Out monitor PD; I can't readily explain why right now. Another thing we noticed is that the optimum pump fiber alignment for the amplifier is not necessarily the optimum alignment for the pump diode monitors; we saw the monitor percentages change while rotating the pump fibers, and most of them peaked when the amplifier output was not maxed (for example, pump diode 2 for Amp1 peaked at 99%, but the best output for the amplifier was achieved at a monitor reading of ~89%).

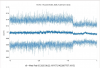

Speaking of the PMC, by making no other changes to the system besides optimizing the pump diode fiber alignment, we saw an immediate improvement to our reflected power. Ryan did a quick tweak while in the enclosure which brought the reflected power down to ~24 W, and a more detailed alignment in the Control Room brought the reflected power down to ~23.6W. At the time we completed this work (~12:30pm PST) and with the ISS ON and diffracting ~4.1%, we had 104.9 W transmitted from the PMC and 23.6 W reflected (at the start of the day there was ~101.7 W transmitted and ~27.2 W reflected). As a check to see how the PMC would react to changes in injection current, we lowered the Amp1 currents from 9.0 A and 8.8 A to 8.8 A and 8.8 A (bringing the injection current more in-line with where we were at install). This brought PMC Refl down by ~0.5 W. We then brought the Amp2 injection currents down to 8.6 A from their current 9.1 A; this skyrocketed the PMC reflected power to ~30 W. So bringing Amp1 more in-line with its install configuration makes PMC Refl better, but then bringing Amp2 more in-line with its install configuration makes PMC Refl much worse. Huh. We returned the injection currents back to where we've had them (9.0 A and 8.8 A for Amp1, 9.1 A and 9.1 A for Amp2).

There is still mode matching work to do, as can be seen by the shape of the PMC Refl spot. We will have to do that at a later date since that is time consuming work (we would have to do it all in one go, Amp1 -> Amp2 then Amp2 -> PMC, which will likely take longer than a 4-hour maintenance window).

NOTE: We did not recalibrate the pump diode monitors, as we left the injection currents where we have been running the system. However, the percentage readings of the monitors did not come back to where they were before we started today's work. We will recalibrate these monitors once we decide if we want to change the injection currents. So for now the pump diode monitor percentages are not truly representative of where we are running the pump diodes (and as I think today's work has shown, they never really have).

This closes LHO WP 12315.